Laser Welding Machine for medical equipment

Machine Features:

The Application of Laser Welding Machine in the Medical Device Industry

Laser welding machines, as an advanced welding technology, have been widely used in the medical device industry. The following is a detailed introduction to the application of laser welding machines in the medical device industry.

Welding of surgical instruments

Laser welding machines play an important role in the manufacturing of surgical instruments. Surgical instruments need to have high precision and reliability to ensure safety and effectiveness during the surgical process. Laser welding machines can achieve high-precision welding, ensuring the quality and consistency of each welding point, and avoiding problems such as deformation and cracks caused by traditional welding methods. At the same time, laser welding machines can also achieve welding of various types of surgical instruments, meeting the needs of different surgeries.

Dental equipment welding

The manufacturing of dental instruments requires precise craftsmanship and high-quality materials to ensure patient safety and treatment outcomes. Laser welding machines can achieve high-precision welding of dental instruments, avoiding problems such as deformation and errors caused by traditional welding methods. At the same time, laser welding machines can also achieve welding of various types of dental instruments, meeting the needs of different types of dental treatment.

Welding of orthopedic plants

Orthopedic implants are medical devices used to treat diseases such as fractures, which require high reliability and stability. Laser welding machines can achieve high-quality welding of orthopedic plants, avoiding problems such as deformation and cracks caused by traditional welding methods. At the same time, the laser welding machine can also achieve various types of orthopedic implant welding, improving the surgical effect and the quality of life of patients.

Welding of interventional medical devices

Interventional medical devices are precision medical devices that require high-precision manufacturing and processing. Laser welding machines can achieve high-precision welding of interventional medical devices, avoiding problems such as deformation and errors caused by traditional welding methods. At the same time, laser welding machines can also achieve welding of various types of interventional medical devices, improving surgical effectiveness and patient safety.

In short, laser welding machines have been widely used in the medical device industry, bringing revolutionary changes to the manufacturing of medical devices. It not only improves production efficiency and reduces production costs, but also improves product quality and safety. With the continuous progress of technology and the increasing demand for applications in the future, the application prospects of laser welding machines in the medical device industry will also be more broad.

Machine Details

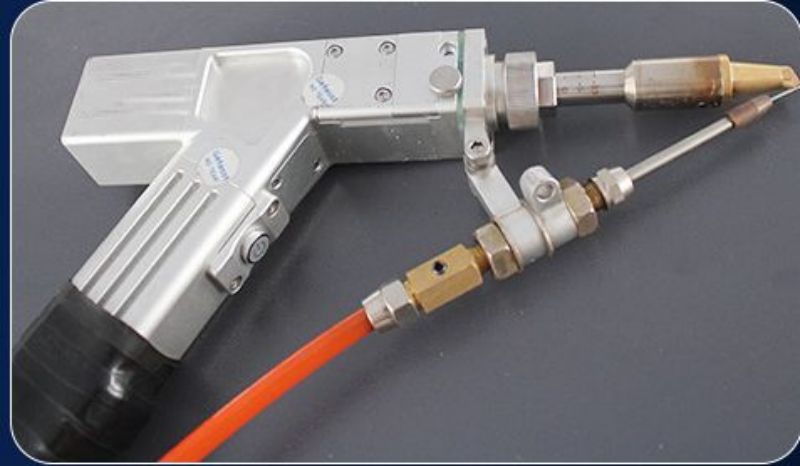

Intelligent welding joint

The fourth generation of intelligent welding head weighs only 0.8KG, long-term operation is not tired, and the double-water cycle design has good cooling effect and good stability

Double protective lenses

Longer life, effectively protect the focusing mirror and QBH head, effectively reduce the damage of other parts of the welding head caused by improper operation when the protection lens is damaged

The button of our fourth generation welding head adopts anti-accidental touch safety technology to prevent the laser output caused by accidentally touching the button, which is safer to use

Wire feed nozzle

The feed nozzle adopts anti-bias design in the process of use to effectively prevent the welding quality caused by the deviation of the welding wire

Control System

The V5.2 version of the control system can quickly adjust various parameters of the machine and the machine state can be clearly seen. The process parameters can save multiple sets of data for easy use and support multi-language switching

Fiber laser

Multiple brands of fiber optic excitation

Optical device, for customers to choose freely, also can choose imported laser brand.

Wire feeder

How the welding spot is welded out is very important to the wire feeder, our company's wire feeder uses a stepper motor to drive strong and powerful, to avoid the wire feed. Problems such as unstable wire feeding

TECHNICAL PARAMETER

| Product brand | HRC Laser |

Product name |

Handheld laser welding machine |

| Welding method | Hand-held welding (automatic) | welding depth | 0.8-10MM |

| Welding width | 0.5-5MM | To help locate | red light |

| Welding gas | Argon Nitrogen compressed air (no water) | welding speed | 1-120MM/S |

| Optical fiber length | 10M | The thickness of the welding plate |

0.3-10MM |

| Cooling mode | Water-cooled | power demand | 220V/380V 50/60Hz |

| Equipment size | 1200*650*1100MM | Equipment weight | 160-220KG |

| Weld form | butt welding; lap welding; rivet welding; roll welding;

T welding; overlap welding,;edge welding,;etc |

||

| Welding materials | Stainless steel, iron, carbon steel, aluminum, aluminum alloy, copper, galvanized sheet | ||

SAMPLE DISPLAY

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.