Laser Welding Machine for hardware processing

TECHNICAL PARAMETER

The Application of Handheld Laser Welding Machine in the Hardware Processing Industry

Introduction

With the continuous development of technology, laser technology has penetrated into various industry fields. Among them, laser welding technology has been widely applied in the hardware processing industry. Handheld laser welding machines, as an advanced laser welding equipment, have gradually occupied an important position in the hardware processing industry due to their advantages of high efficiency, flexibility, and precision.

Introduction to Handheld Laser Welding Machine

The handheld laser welding machine is a portable and efficient laser welding equipment. It uses a high-energy laser source, transmitted through optical fibers, and accurately aimed and adjusted by advanced control systems. The handheld laser welding machine has the advantages of simple operation, strong adaptability, fast welding speed, and high welding quality.

Application in the hardware processing industry

Efficiency: The handheld laser welding machine can complete high-quality welding operations in a short period of time, greatly improving production efficiency.

Diversity: Handheld laser welding machines can handle various hardware materials, such as stainless steel, aluminum alloy, copper alloy, etc. At the same time, it can also handle various complex welding forms, such as spot welding, butt welding, fillet welding, etc.

Precision: The handheld laser welding machine can achieve precise aiming and adjustment, thereby ensuring the accuracy and quality of welding.

Environmental friendliness: The handheld laser welding machine does not produce harmful substances during the welding process and meets environmental requirements.

Labor saving: The handheld laser welding machine has a high degree of automation, which can reduce dependence on skilled workers and save labor costs.

Conclusion

The advantages of handheld laser welding machines have broad application prospects in the hardware processing industry. It can not only improve production efficiency, but also cope with various complex welding needs. At the same time, its environmental friendliness and labor-saving characteristics also make it an ideal choice for the hardware processing industry. With the continuous development of technology, the performance and functions of handheld laser welding machines will also be further improved and improved, and their application in the hardware processing industry will also be more extensive and in-depth.

Live Show

MACHINE DETAILS

High performance brand fiber laser

Longer life, higher electro-optical conversion rate, 24 hours continuous work, long dimensional-free cycle, reduce maintenance costs

High quality handheld laser welding head

Lightweight and flexible, long-term work without fatigue, matching welding copper nozzle and infrared positioning, to achieve any part, Angle welding.

Lengthened welded connection optical fiber

Equipped with 5~10 meters brand optical fiber can achieve ultra-long distance operation can reach a wide distance, flexible and convenient.

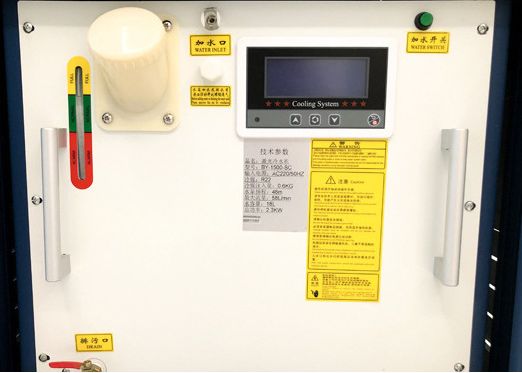

LCD panel control system

Simple and clear, preset a variety of process modes, without complex training, easy to master, preset multiple security alarms, more reliable.

Manual button control switch

One-key boot, simple and easy to use, multi-parameter adjustment range, long life, more practical.

Built-in intelligent double temperature laser chiller

Intelligent temperature control, dust and condensation prevention, rapid cooling, no trace of hot air, stable performance, energy saving, improve the service life of the equipment.

Automatic wire feeder

Fast wire feeding, wire feeding specifications include 0.8/1.0/1.2/1.6 four specifications, wire feeding speed is adjustable, equipped with manual wire feeding/withdrawal function.

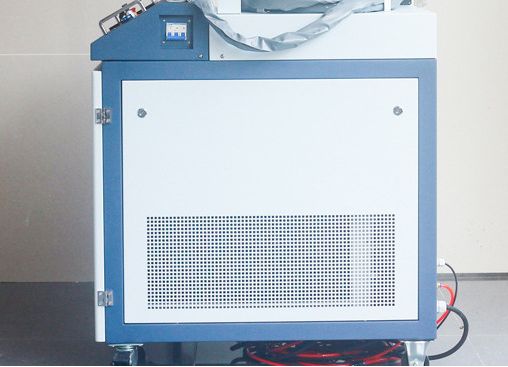

Sheet metal cabinet

Protection is convenient for single work

The industry meets the size ratio of industrial needs

APPLICATION

widely used in most mainstream industries

Widely used in kitchen utensils, door and window guardrail, stair elevator, stainless steel, hardware board Materials, craft gifts, automobiles, aerospace and other industries

Kitchen, bathroom and utensils

Advertising industry

Auto parts industry

Metal Mold

INTRODUCE FOR WELDING METHODS

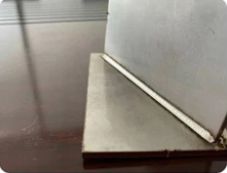

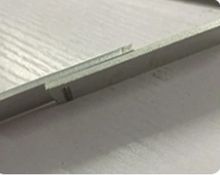

Sheet metal outer corner welding

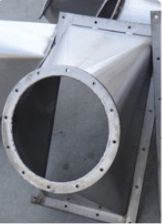

Stainless steel 360-degree welding

Welding of aluminum alloy doors and Windows

Stainless steel inside corner welding

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.