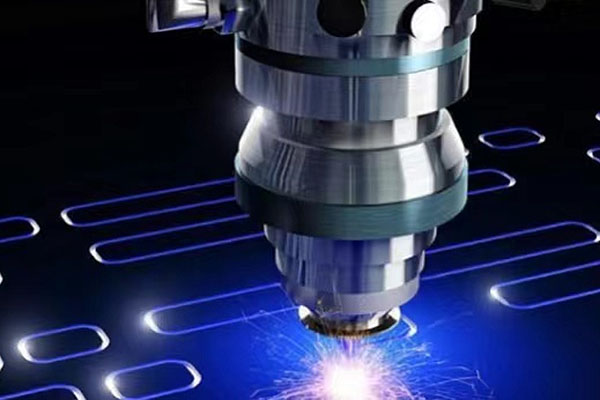

Laser marking technology is one of the largest application areas of laser processing. With the rapid development of the secondary industry, lasers are widely used in various processing and manufacturing industries, such as laser marking, laser cutting, laser welding, laser drilling, laser proofing, laser measurement, laser engraving, etc. While accelerating the production of enterprises, it also accelerated the rapid development of the laser industry.

The ultraviolet laser has a wavelength of 355nm, which has the advantages of short wavelength, short pulse, excellent beam quality, high precision, and high peak power; therefore, it has natural advantages in laser marking. It is not the most widely used laser source for material processing like infrared lasers (wavelength 1.06 μm). However, plastics and some special polymers, such as polyimide, which are widely used as substrate materials for flexible circuit boards, cannot be finely processed by infrared treatment or "thermal" treatment.

Therefore, compared with green light and infrared, ultraviolet lasers have smaller thermal effects. With the shortening of laser wavelengths, various materials have higher absorption rates, and even directly change the molecular chain structure. When processing materials that are sensitive to thermal effects, UV lasers have obvious advantages.

Grid laser TR-A-UV03 water-cooled laser can provide 355nm ultraviolet laser with an average output power of 1-5W at a repetition rate of 30Khz. The laser spot is small and the pulse width is narrow. It can process fine parts, even at low pulses. Under the energy level, high energy density can also be obtained, and material processing can be carried out effectively, so more accurate marking effect can be obtained.

The working principle of laser marking is to use high-energy-density laser to partially irradiate the workpiece to vaporize the surface material or undergo a photochemical reaction of color change, thereby leaving a permanent mark. Such as keyboard keys! Many keyboards on the market now use inkjet technology. It seems that the characters on each key are clear and the design is beautiful, but after a few months of use, it is estimated that everyone will find that the characters on the keyboard begin to become blurred. Familiar friends, it is estimated that they can operate by feeling, but for most people, the key blurring may cause confusion.

(Key Board)

The 355nm ultraviolet laser of Gelei Laser belongs to the "cold light" processing. The water-cooled ultraviolet laser laser head and the power supply box can be separated. The laser head is small and easy to integrate. . Marking on plastic materials, with advanced non-contact processing, does not produce mechanical extrusion or mechanical stress, so it will not damage the processed items, and will not cause deformation, yellowing, burning, etc.; thus, it can be Complete some modern crafts that cannot be achieved by conventional methods.

(Key board marking)

Through remote computer control, it has extremely superior application characteristics in the field of special material processing, can significantly reduce thermal effects on the surface of various materials, and greatly improve processing accuracy. Ultraviolet laser marking can print various characters, symbols and patterns, etc., and the character size can range from millimeters to microns, which also has special significance for product anti-counterfeiting.

While the electronic industry is developing rapidly, the process technology of industry and OEM is also constantly innovating. The traditional processing methods can no longer meet people's increasing market demand. Ultraviolet laser precision laser has small spot, narrow pulse width, small heat impact, High efficiency, energy conservation and environmental protection, precision machining without mechanical stress and other advantages are ideal improvements to traditional processes.

Post time: Nov-17-2022